Monoblock Pumps Frequently Asked Questions

A monoblock pump is a centrifugal pump, wherein the rotating parts of the pump are directly mounted on the shaft of the prime mover (motor). A single shaft design helps in reducing transmission losses.

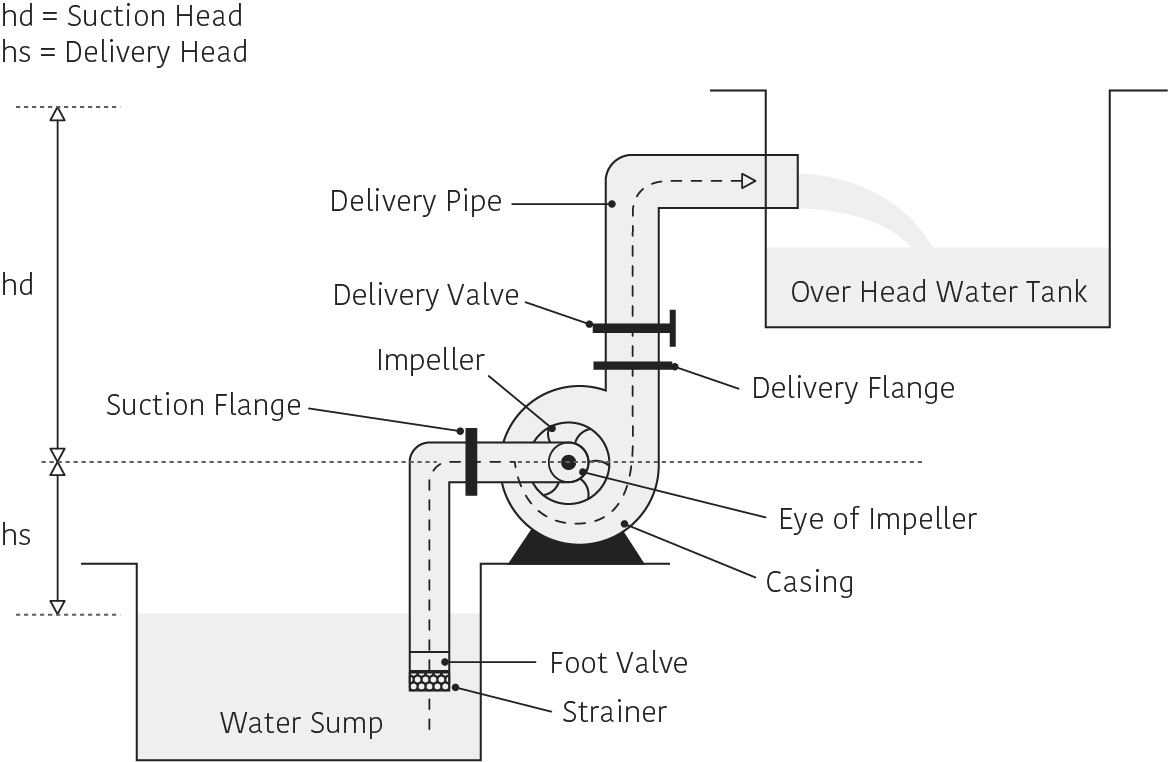

In a monoblock pump, the impeller mounted on the prime mover shaft rotates, and a suction lift is created at the eye of the impeller. Water gains kinetic energy from the impeller vanes, exits and passes through a volute, wherein the kinetic energy is converted to pressure (head).

The suction lift in a monoblock pump is a measure of the pressure gradient between the hydraulic centre of the pump and the water surface on the suction side. This is a negative pressure and is limited by the atmospheric pressure (10.3 m) at the exit of the pump. However, consider the friction losses in the pipeline, the suction lift is limited to 7 m.

Before buying a pump, ensure that you match every aspect of the pump to your requirement.

Given below are some the key considerations while selecting a monoblock pump:

- Identify the source from which water has to be pumped (river / well / tank). The water availability in the source should match the pump flow rate.

- Head: The total head is calculated as below

- Total Head = Suction Head + Delivery Head + Friction Loss + Fitting Losses

- Suction Head – From water surface to pump suction point.

- Delivery Head – From pump to delivery point.

- Friction Loss – Loss of head due to flow through pipe line.

- Fitting Loss – Loss of head due to the interruption of various fittings. (Gate value, Check value & Bends)

While calculating the friction losses, consider the length of both vertical and horizontal pipe (until the delivery point).

- Delivery pipe size: Delivery pipe size is the diameter of the pipe at pump outlet. It is measured in inches or millimeters.

If there is an existing pipeline, the new pump has to match the delivery size.

If it is a new pipeline, the delivery size will be decided depending on the distance to which the water must be delivered.

- Material of construction: The pump should be chosen based on the application. Material of construction is important for reliability of the pump.

Click here for specifications of monoblock pumps. Find out more about our products by clicking here. For more detailed specifications, please contact our Customer Care through toll free number 1800-102-8888.

Monoblock pump may not be pumping water due to one or more of the following reasons

- Faulty foot valve

- Pump not primed

- Air leakage on the suction side

- Suction lift too high

- Foot valve not sufficiently submerged

- NRV is jammed

The pump may not be working due to one or more of the following reasons:

- No power supply to the motor

- Motor coil burnt

- Low voltage operation

- Overload relay tripped in the starter

- Fuse has blown

- Loose connections

Monoblock pumps are available for sale in open market through dealers.

Taro pumps can be bought from our authorised dealer. Please click the link to get the nearest Texmo Industries Authorised Dealer or contact our Customer Care through toll free number 1800-102-8888.

Monoblock pumps are available for sale in open market through dealers. You can get the product price details from dealers.

In order to know the price of Taro Pumps, please get in touch with our authorised dealer. You can access the location here contact our Customer Care through toll free number 1800-102-8888.

We have a troubleshooting guide that you can use to try and rectify a fault, you’ll find information and downloads specific to your type of pump here. Should you need further help, click here to find more information on how to contact us.