How to install a Monoblock Pump

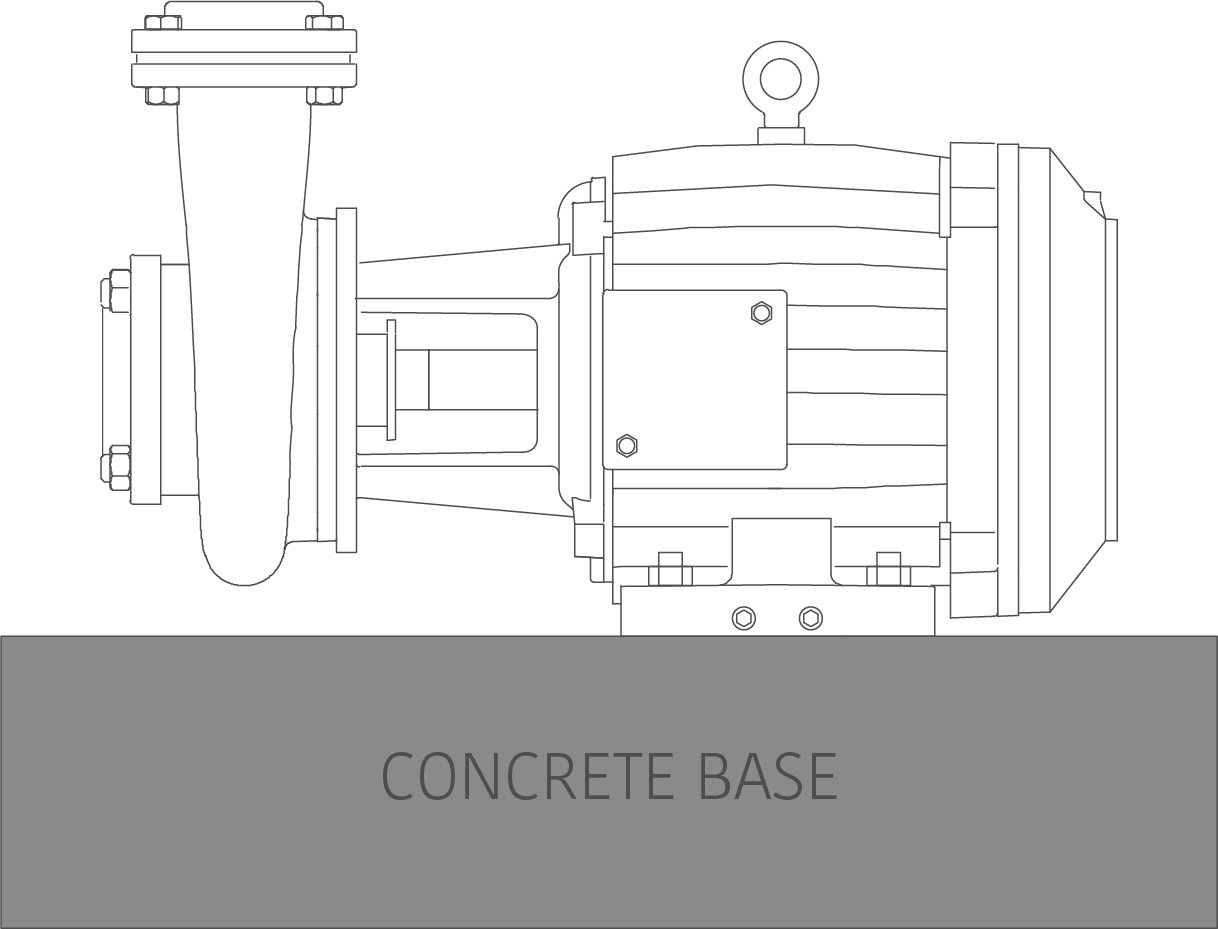

- Prepare a level concrete foundation for mounting the Monoblock and tighten the motor base using the foundation bolts as shown in Fig. 1 below:

- Use prescribed pipe sizes as mentioned on the product name plate

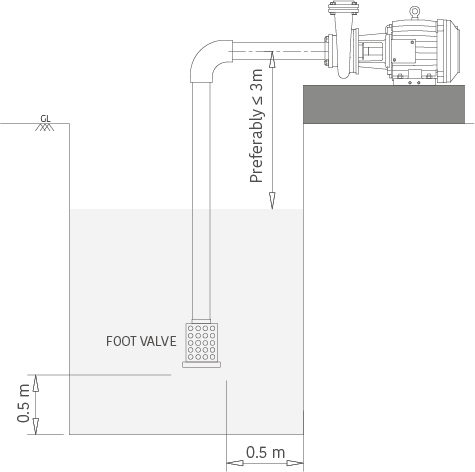

- Place the pump center line to the water surface 3 - 6 meter distance

- The foot valve fixed above the bottom of the well. Refer Fig. 2, shown below, for recommendations:

- Use as few pipe fittings as possible in the suction line and use a good quality foot valve to reduce suction losses.

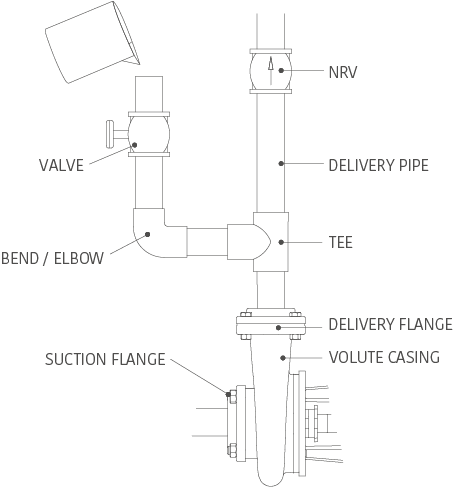

- Provide a priming facility in the pipe line adjacent to the pump discharge flange as shown in Fig. 3 below and during priming, check the pump suction pipe for leakages.

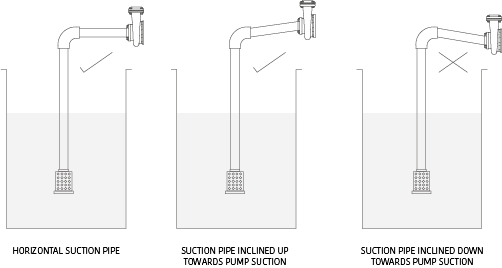

- Ensure that the suction pipe connected to the pump suction flange is horizontal or sloping upwards towards the pump suction flange to prevent air lock. A pipe sloping downwards towards the pump suction flange will result in air lock. Refer Fig. 4, shown below, for the preferred suction pipe orientation.

Different Positions of the Suction Pipe - In case the installation has a high static delivery head, mount a good quality NRV in the delivery line as close as possible to the pump delivery flange.

- Ensure pump casing filled with water for priming

- Connect the Monoblock to the starter and power up the Monoblock.

- In Three phase Monoblock, Check the direction of rotation of the motor shaft. If the direction of rotation is in the same direction as that marked on the volute casing, the connections are right.

- In case the direction of rotation of the motor shaft does not match the marking on the volute casing, interchange any two lead wires at the starter and confirm the direction of rotation.as before.

- Electrical Installation

- Ground the Monoblock using the two earth screws provided on the leg of the motor body

- Ensure electrical joints, if any, are properly and adequately insulated

- Connect the cable properly to the starter terminals to avoid loose connections

- Factor in low voltage operation while selecting cable size

- Power cable connection to three phase monoblock - direct on line an star-delta connection. Refer Fig. 5, in the guide, for connecting the lead wires to the Terminal Board of the three phase monoblock..

- Power cable connection to 1φ CSR high speed monoblock

- The motors are internally wired and pre-connected with the capacitor leads with two leads emerging out from the Terminal Box Cover

- Only Phase and Neutral need to be connected to these two leads (A1 & A2)

Monoblock Pumps Overview

Centrifugal Monoblock Pumps are a popular type of water pumps used in India. They gain their name due to the fact that they work through a centrifugal force from its centrifugal electric motor.

OverviewCompare Monoblock Pumps

We have provided a range of comparisons, pitting Monoblock pumps against popular alternatives. Here we compare the advantages/ disadvantages, usage differences, installation and much more to help you make the right choice.

ComparisonsFrequently Asked Questions

If you have any questions regarding Monoblock pumps, then this is the resource for you. Here we answer the most commonly asked questions in detail, leaving you safe in the knowledge of whether a Monoblock pump is right for you.

FAQs